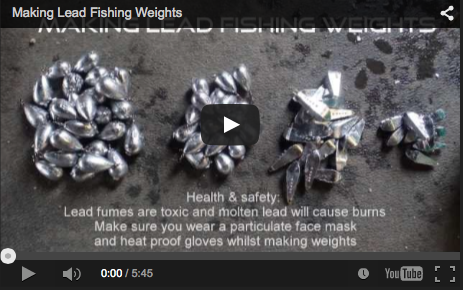

Firstly, and most importantly, you will need a particulate face mask/respirator. Lead fumes are toxic and can make you seriously ill - do not make weights without wearing one! They can be purchased online or from most hardware stores for around £20. Melt the lead in a well ventilated space and take regular fresh air breaks. Your hands also need protection from the heat. Lead melts at a reasonably low temperature compared to other metals, at 327.5 degrees celsius, but that is way more than enough to cause serious burns and a trip to hospital. Invest in some heat proof gloves - £10 should get you a pair. You can't make weights without them. It is also important to mention that any lead you add to the melting pot must be dry - if liquid water comes into contact with molten lead it evaporates at such a rate it causes the lead to spit and explode from the pot. You can wear googles and an apron/thick jacket but as long as your careful and not splashing the molten lead, and any lead you add to the melting pot is dry, you will be ok. Secondly you need a source of lead. If your lucky enough to be one, or know a builder then you will have access to scrap lead. If not then lead can be brought at a reasonable price from your local scrapyard. The price has fluctuated over the past few years but has steadily been increasing and is currently around £1-£1.25 a kilogram. I usually buy £10-20 worth for a weight making session. If you can, ask for clean lead. If its coated in muck its not too much of a problem but clean lead makes life easier. The lead will often come in sheets or strips and will need to be cut into smaller pieces to fit into a melting pot. I use a bench guillotine but a pair of metal snips (below) will also do the job too. Next you need a means to melt your lead. I use a simple gas cooking ring linked up to a bottle of gas. A basic cooking ring can be picked up online or sometimes at a car boot sale. Gas bottles, gas regulators and piping can be brought from some petrol stations and DIY stores. These are set up on a bench lined with aluminium sheeting (inexpensive from a local metal supplier). You could set it up on a concrete floor but i find it easier working when standing up. Cast iron saucepans are used for melting the lead - one with a lip for pouring. I have two gas rings set up - one to keep lead melting on to replenish the pouring pot on the other ring. I use a thermalite block to place the moulds on when pouring, you could equally use a standard brick. This is set up in a garage but next top a door to provide sufficient ventilation. Once the lead has melted you need to scrape off the slag (muck and impurities) that will have floated to the top. The cleaner the lead the less slag. As previously said, try to get clean lead if you can. I use a trowel to scrape it off into a metal ladle, once its all removed it gets thrown into a metal waste pot. You should now have a pot of clean molten lead ready for pouring into your mould. Make sure you heat the mould up before pouring your first lot of lead into it otherwise the weight may not form properly or the pouring hole may seal over. Just place the mould beside the saucepan on the ring whilst the lead is melting to heat it up. I use a Do-It mould to make 6oz & 8oz Swivel Bombs and standard aquapedo moulds to make 3oz, 4oz & 5oz weights. The Do-It moulds are expensive but incredibly easy to use. The swivel bomb mould, unsurprisingly, requires a swivel, the aquapedo weights require a brass loop, these can be purchased from most tackle shops in packs of 50 or 100 for a few pounds. The Do-It mould is hinged so the two halves of the mould can easily and quickly be put together. The standard moulds can be a little tricky to put together without knocking the loop out of place. A simple task made difficult when wearing heat proof gloves! Make sure the mould is fully closed or else lead will pour out. A small G-clamp can come in handy to stop the mould falling apart. Its now time to pour the lead into the mould. The melting pot will be heavy so grip the handle firmly with both hands. Slowly pour the lead into the mould until it emerges from the top. If the mould is too cold the entrance hole may seal up so you will need to start again. Give it 10 seconds or so for the lead to solidify. Open the mould to see if the lead has formed properly and filled the entire mould. At this point the mould will be at its hottest and you will sometimes find your fingers getting hot through the gloves. Take them off and let them cool down. I have often ejected a glove from my hand at high speed because it has become to hot! The weights will be scorching hot and can sometimes be difficult to remove from the mould, especially if some of the lead has creeped out from the mould when pouring. Use a trowel or knife to prise the lead from the mould. Once free i transfer them straight into a metal bucket of cold water. It takes a while to get the hang of it but once you find rhythm you will soon get through a pot of lead. Make weights until the pot is about 25% full, then add new lead and wait for it to melt before starting the process again. A few hours later and you will have made plenty of weights. Now its time to use metal snips to remove the lead pieces that formed in the pouring hole and any other unwanted pieces of lead from the weights. Place all these scrap pieces in a pot and they can be used for next time. Before long you will have a pile of shiny new homemade lead weights! A mornings worth of weight making will probably produce enough weights to last me the year, with some to hand out to others along the way. Quite a few items need to be brought to set up a lead making station like the one shown here but in the long run you save a lot of money over buying weights. The most essential items are the particulate face mask and heat proof gloves! So if you use lots of weights then start building up the equipment to make your own! Here is a video outlining how i make my lead fishing weights. Check it out!

Gavin

8/4/2015 13:16:41

a great reference, how much do you reckon each weight costs to produce?

Cornish Kayak Angler

8/4/2015 14:13:59

Hi Gavin, 6/2/2019 06:38:54

Making your own fishing lures is a great way to have fun, save money, extend your fishing season and catch more fish. The methods you have used here, I think its one of the best way to make own fishing lead. Comments are closed.

|

AuthorLiam Faisey My Tackle ShopSPONSORSProudly associated with

Cornwall's only specialist kayak fishing shop

Archives

March 2023

Categories

All

Add my blog to your feed reader by clicking the button below

Get blog updates via email

Kayak Fishing VideosCustom feed reader powered by FeedWind

Useful Links

Anglers Afloat

Cornish Shore & Kayak Fisherman Cornwall Canoes Palm Equipment Penzance Kayak Fishing Meet Info Saltwater Kayak Fisherman Magic Seaweed XC Weather |

|

Website powered by pasties and the hope of good weather!

© 2023 Liam Faisey

© 2023 Liam Faisey

RSS Feed

RSS Feed